Roasting is not pasteurization

In the agri-food sector, thermal processes are at the core of microbiological control strategies. Yet one of the most common pitfalls is assuming that roasting and pasteurization share the same objectives and outcomes. In reality, these are fundamentally different treatments: confusing one with the other can lead to serious risks for product quality and compliance.

Why this distinction matters

Pasteurization is a controlled thermal treatment designed to destroy pathogenic and non-pathogenic microorganisms in ingredients. Its purpose is to ensure food safety.

Roasting, on the other hand, is a dry-heat process that alters the taste, aroma, and organoleptic characteristics of products. But on its own, it is insufficient to guarantee effective pasteurization: hot air only provides a 2-log reduction—far from the 5-log reduction required to control the risk of salmonella.

Choosing roasting instead of pasteurization may result in:

-

not reaching the required microbiological reduction levels,

-

allowing bacteria, yeasts, or molds to remain,

-

compromising regulatory compliance or consumer safety.

The solution

When your product requires roasting, it is essential to pasteurize first, then roast in order to properly manage microbiological risks.

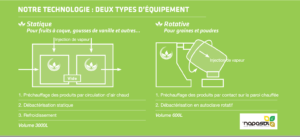

Steripure offers a pasteurization treatment using saturated steam under air vacuum, powered by a unique and innovative technology.

Unlike traditional thermal treatment technologies that rely on only two parameters (temperature and time), Steripure has introduced a third dimension into the pasteurization process: pressure (positive or negative).

Expert control of temperature, time, and pressure simultaneously is the strength of the Steripure process. Mastering these three key factors ensures a much higher level of efficiency than conventional pasteurization methods.

By controlling pressure inside the pasteurization chamber, Steripure guarantees perfect steam quality for any given temperature—neither too wet nor too dry. Dry steam is ineffective at reducing bacterial load, while overly wet steam can alter product characteristics.

The BÜHLER NAPAROAST system uses saturated steam, which contains five times more energy and enthalpy than water or dry air at the same temperature.

Added value for your business

![]() Avoid costly recalls and associated risks

Avoid costly recalls and associated risks

![]() Comply with European regulations

Comply with European regulations

![]() Enhance your product by guaranteeing safety

Enhance your product by guaranteeing safety

Want to learn more?

👉 Contact our experts to discuss your project.

👉 Request a free personalized quote today.