Saturated steam: a powerful solution against pathogens

A recent study published in the International Journal of Food Microbiology demonstrates the effectiveness of saturated steam treatment in eliminating pathogenic bacteria such as Salmonella, Listeria, and E. coli on dried fruits and nuts.

Conclusive results

Low-temperature saturated steam treatment has proven effective in significantly reducing the presence of Salmonella, Shiga toxin-producing E. coli (STEC), and Listeria monocytogenes on macadamia nuts.

Significant bacterial reduction

The study showed that:

– On macadamia nuts, a 5LOG CFU/g reduction of pathogens was achieved.

Saturated Steam, the Steripure Technology: A Method Suitable for Sensitive Foods

This technique offers several advantages for tackling pathogens:

- Consistent treatment from the first to the last kilogram: Reduces microbial load by up to 5LOG.

- Preservation of product properties: Maintains color, taste, and moisture content.

- 100% natural process: Certified organic method by ECOCERT.

Our validations supporting this study:

Currently, we have 18 validations issued by the AQMC laboratory, demonstrating the effectiveness of saturated steam in eliminating Salmonella up to 7LOG CFU/g:

- Seeds: chia, flax, poppy, pumpkin, sesame, sunflower

- Nuts: macadamia, walnuts 5-16, cashew, hazelnut

- Herbs and spices: cinnamon, rosemary

- Powders and fibers: cocoa fiber, psyllium

What is the validation process?

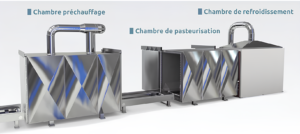

For each selected product, laboratory-contaminated samples are placed on one of our production lines.

- During pasteurization:

temperature and pressure recorders are installed in the chamber to ensure the proper rise in temperature and pressure of the machine. This also helps to validate the uniformity of the method. - After pasteurization

the samples are sent back to the laboratory for analysis. The laboratory then examines the difference in bacterial concentration before and after decontamination. - Post-treatment:

once the microbiological analyses are received, the laboratory writes a study and concludes on the effectiveness of the treatment applied to the material. Depending on this conclusion, the validation is either approved or not.

To learn more about our validations, click here.